Your One-Stop Solution for High-Quality Metal Casting, From Design to Delivery ISO 9001 Certified, 99.2% On-Time Delivery, Get a Quote in 24 Hours.

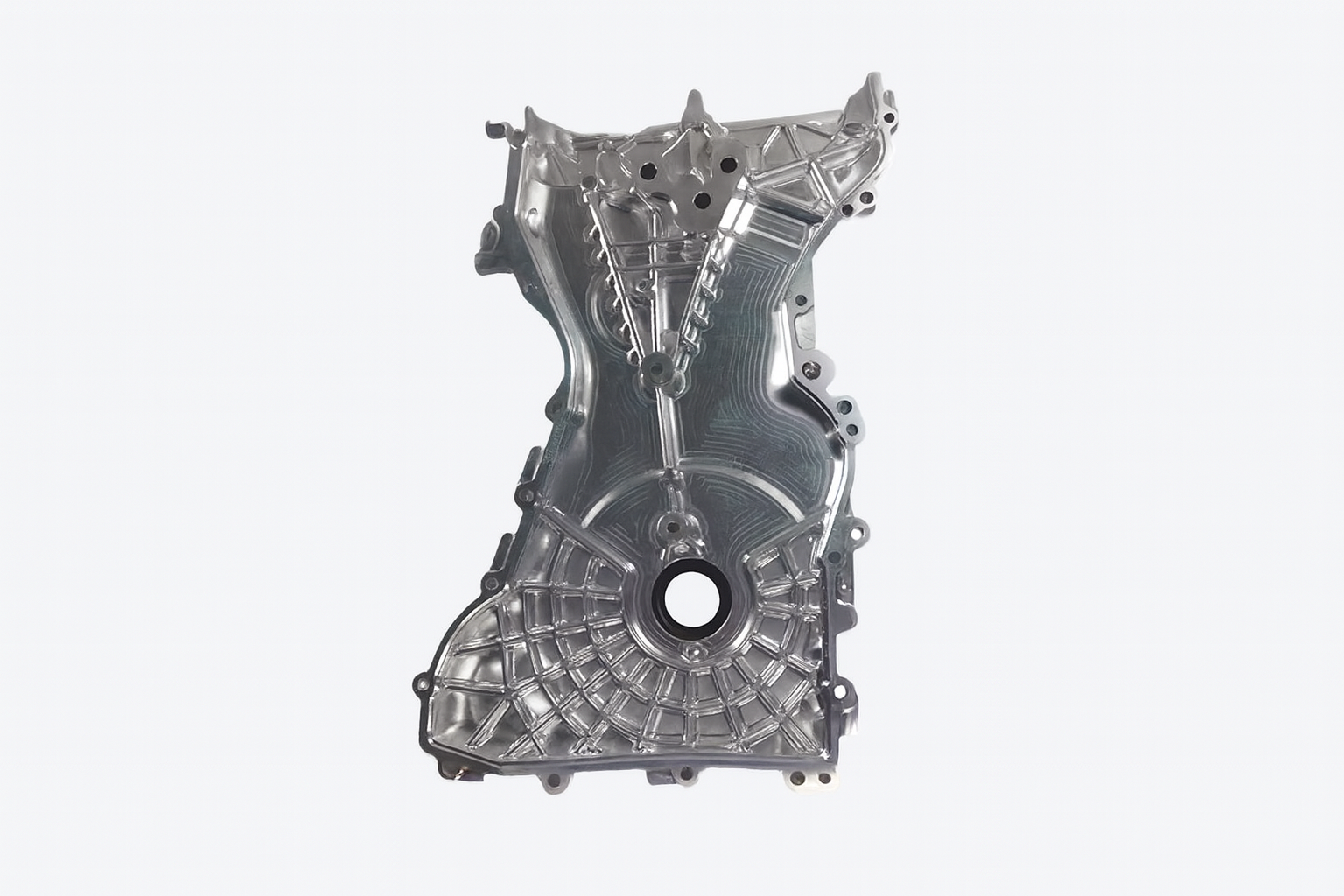

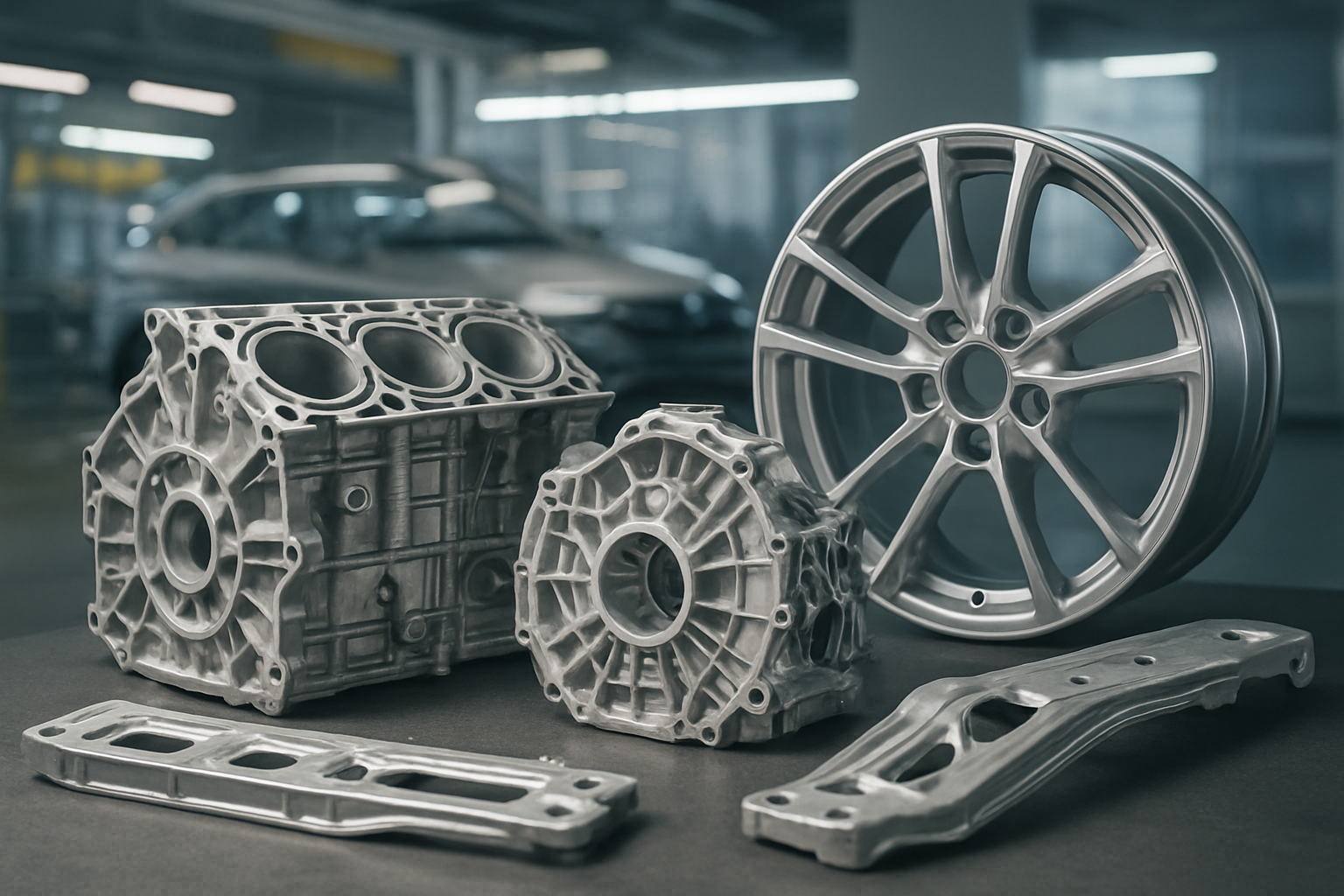

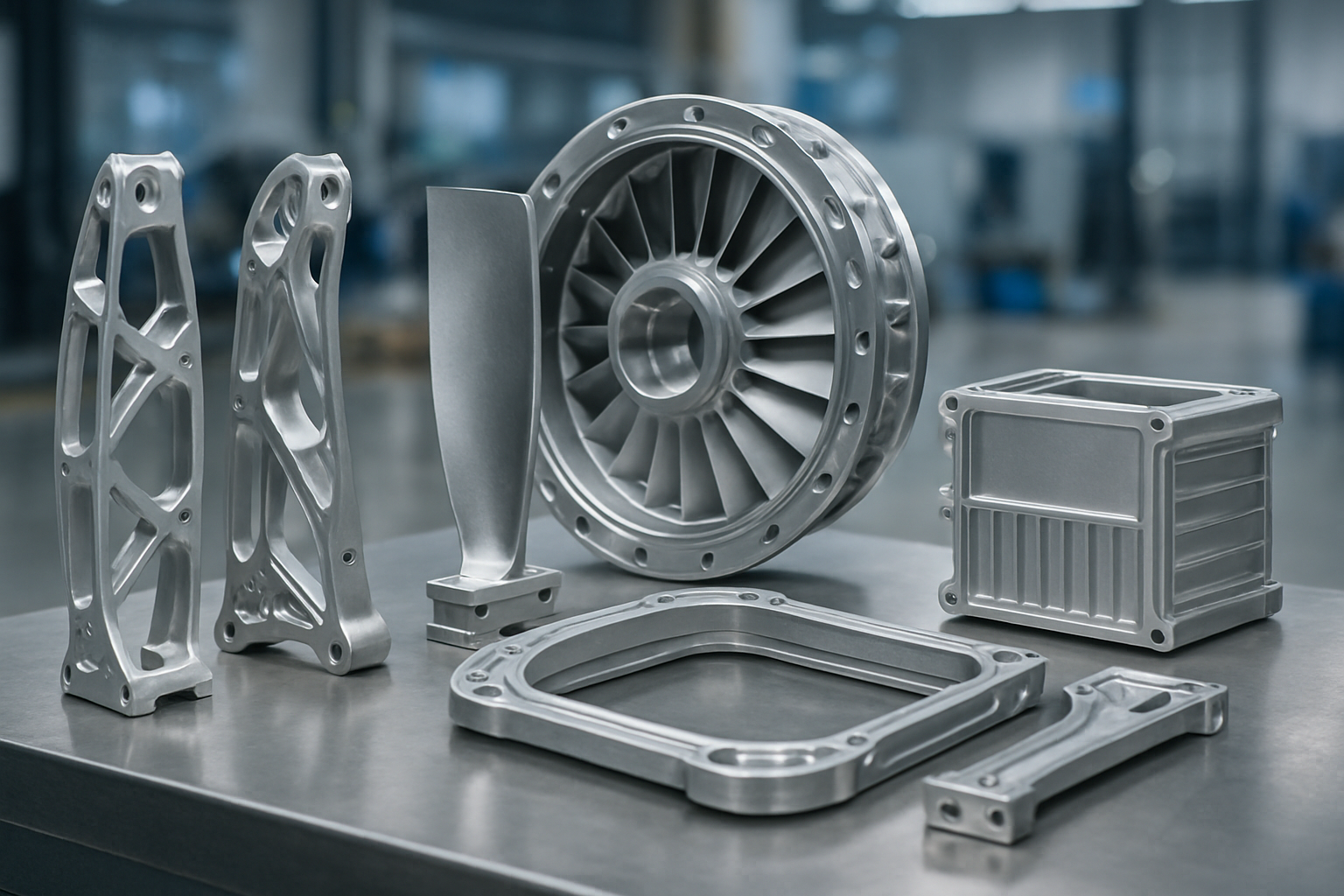

Precision-engineered aluminum components designed for lightweight performance, excellent corrosion resistance, and exceptional strength-to-weight ratio across diverse industrial applications.

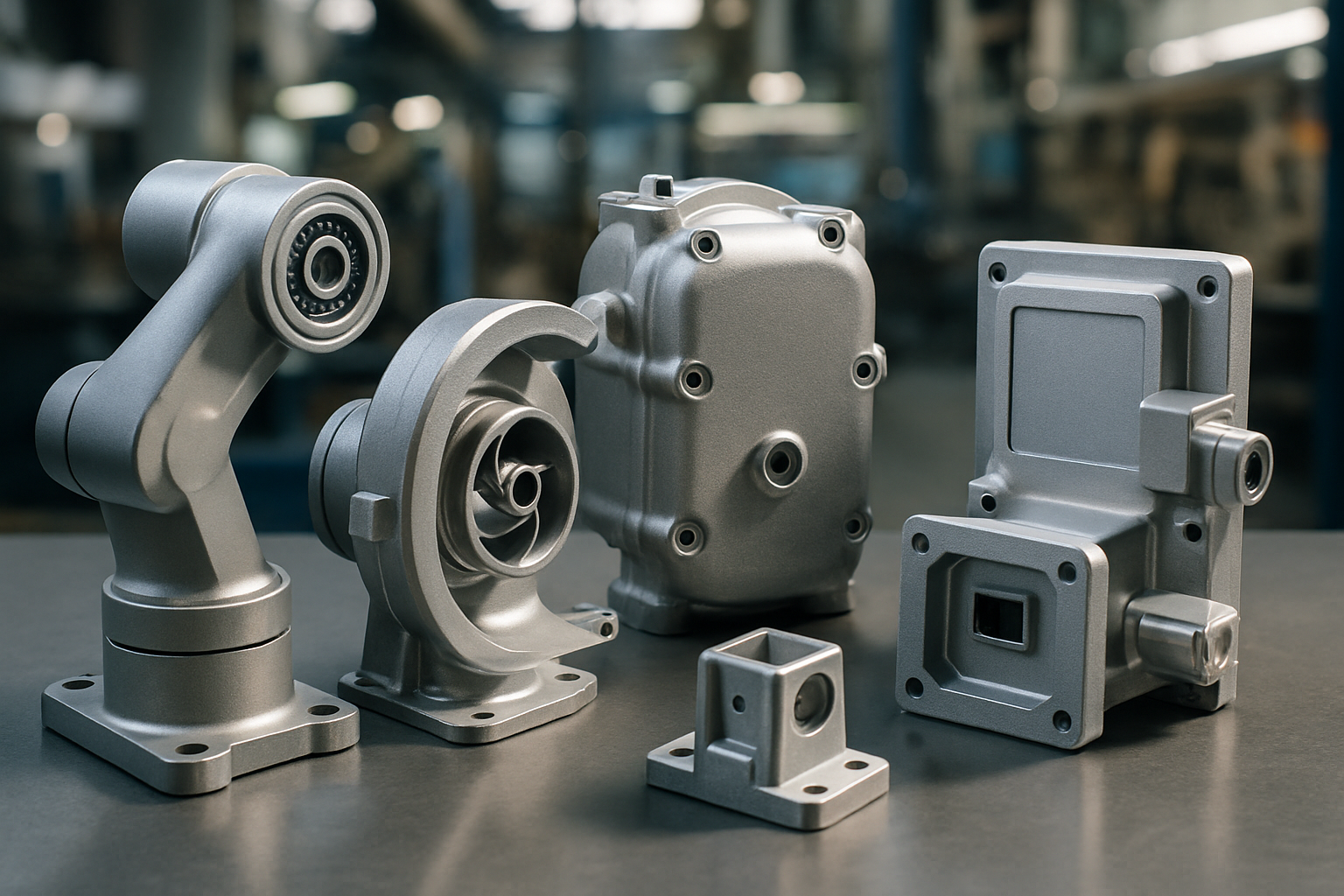

High-performance engine blocks, cylinder heads, and pistons for automotive and industrial engines.

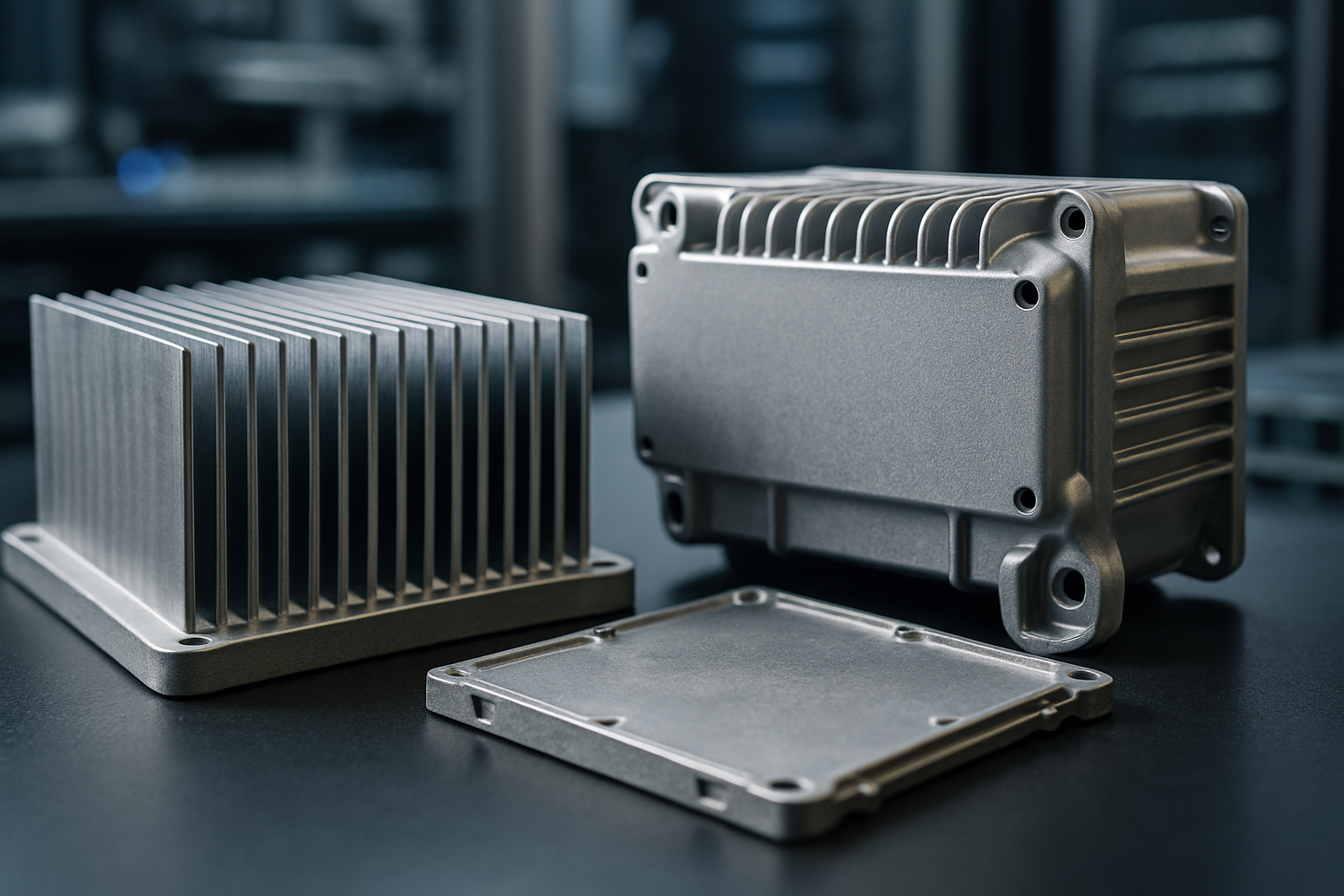

Protective housings and enclosures for electronics, telecommunications, and industrial equipment.

Efficient thermal management solutions for LED lighting, power electronics, and cooling systems.

Lightweight transmission housings, suspension components, and structural automotive parts.

Decorative and functional lighting components with excellent thermal properties and durability.

Corrosion-resistant impellers, casings, and pump housings for water and chemical applications.

High-precision structural parts, brackets, and housings meeting stringent aerospace standards.

Lightweight marine fittings, cleats, and deck hardware with excellent saltwater resistance.

EMI shielding enclosures and protective housings for sensitive electronic equipment.

Comprehensive technical specifications for our premium aluminum casting alloys, meeting international standards and industry requirements for superior performance.

High-strength aluminum alloys optimized for sand casting applications with excellent machinability.

Precision die casting materials with superior dimensional accuracy and surface finish quality.

Premium alloys for investment casting with exceptional detail reproduction and tight tolerances.

Complete technical data for our certified aluminum casting materials

| Alloy Grade | Standard | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Applications |

|---|---|---|---|---|---|

|

A356.0

AlSi7Mg0.3

|

ASTM B26 | 228-262 | 164-207 | 3-5 | Automotive, Aerospace |

|

A380.0

AlSi8.5Cu3.5

|

ASTM B85 | 324 | 159 | 3.5 | General Purpose |

|

A383.0

AlSi10.5Cu2.5

|

ASTM B85 | 310 | 152 | 3.5 | Pressure Tight |

|

A413.0

AlSi12

|

ASTM B85 | 296 | 145 | 2.5 | Excellent Castability |

|

A319.0

AlSi6Cu3

|

ASTM B26 | 185-250 | 125-185 | 1-2 | Engine Blocks |

|

A360.0

AlSi9.5Mg0.6

|

ASTM B85 | 317 | 165 | 5 | High Strength |

Detailed chemical analysis for quality assurance and traceability

| Alloy | Si | Cu | Mg | Fe | Mn | Zn | Al |

|---|---|---|---|---|---|---|---|

| A356.0 | 6.5-7.5 | ≤0.20 | 0.25-0.45 | ≤0.20 | ≤0.10 | ≤0.10 | Balance |

| A380.0 | 7.5-9.5 | 3.0-4.0 | ≤0.10 | ≤1.30 | ≤0.50 | ≤3.0 | Balance |

| A383.0 | 9.5-11.5 | 2.0-3.0 | ≤0.10 | ≤1.30 | ≤0.50 | ≤3.0 | Balance |

| A413.0 | 11.0-13.0 | ≤1.0 | ≤0.10 | ≤2.0 | ≤0.35 | ≤0.50 | Balance |

Our metallurgy experts can recommend the optimal aluminum alloy for your specific application requirements.

From mold design to final inspection, our comprehensive 9-step aluminum die casting workflow delivers exceptional precision components with superior surface finish and dimensional accuracy.

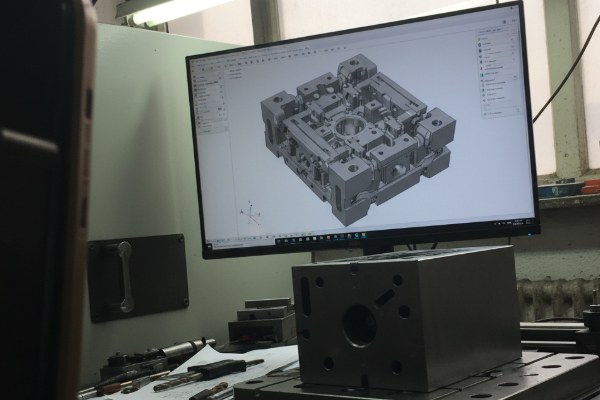

Precision mold design based on industrial standards with complete structure and simple design.

High-precision mold manufacturing following design specifications with strict quality requirements.

Mold installation on casting equipment with precise parameter adjustment for optimal precision.

Premium aluminum alloy materials preparation including ADC12 and A380 grades.

Precision molten aluminum injection with controlled temperature and measurement.

Rapid controlled cooling to achieve optimal part quality and dimensional stability.

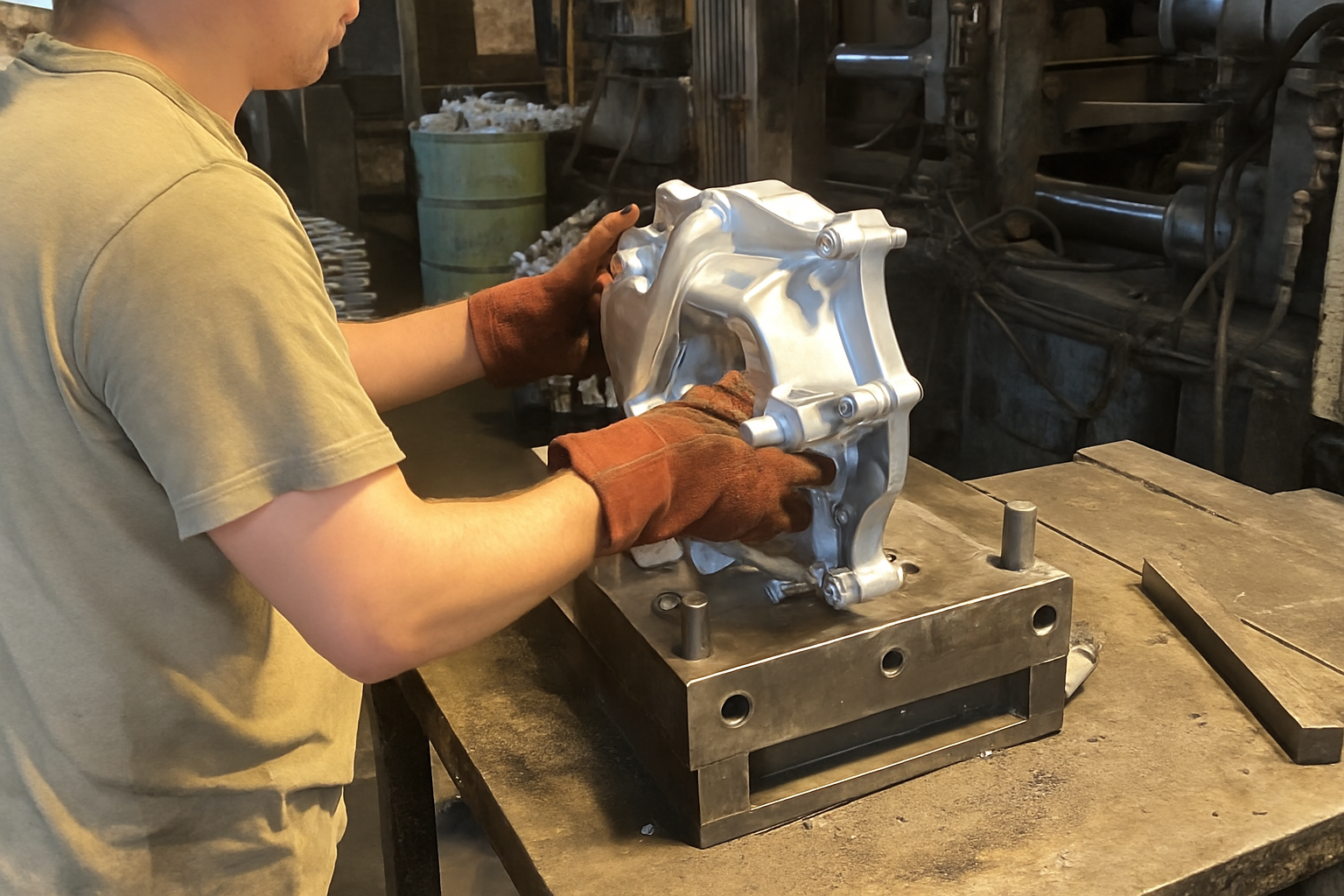

Careful ejection of formed aluminum parts from the die casting mold.

Comprehensive surface finishing including trimming, machining, and coating applications.

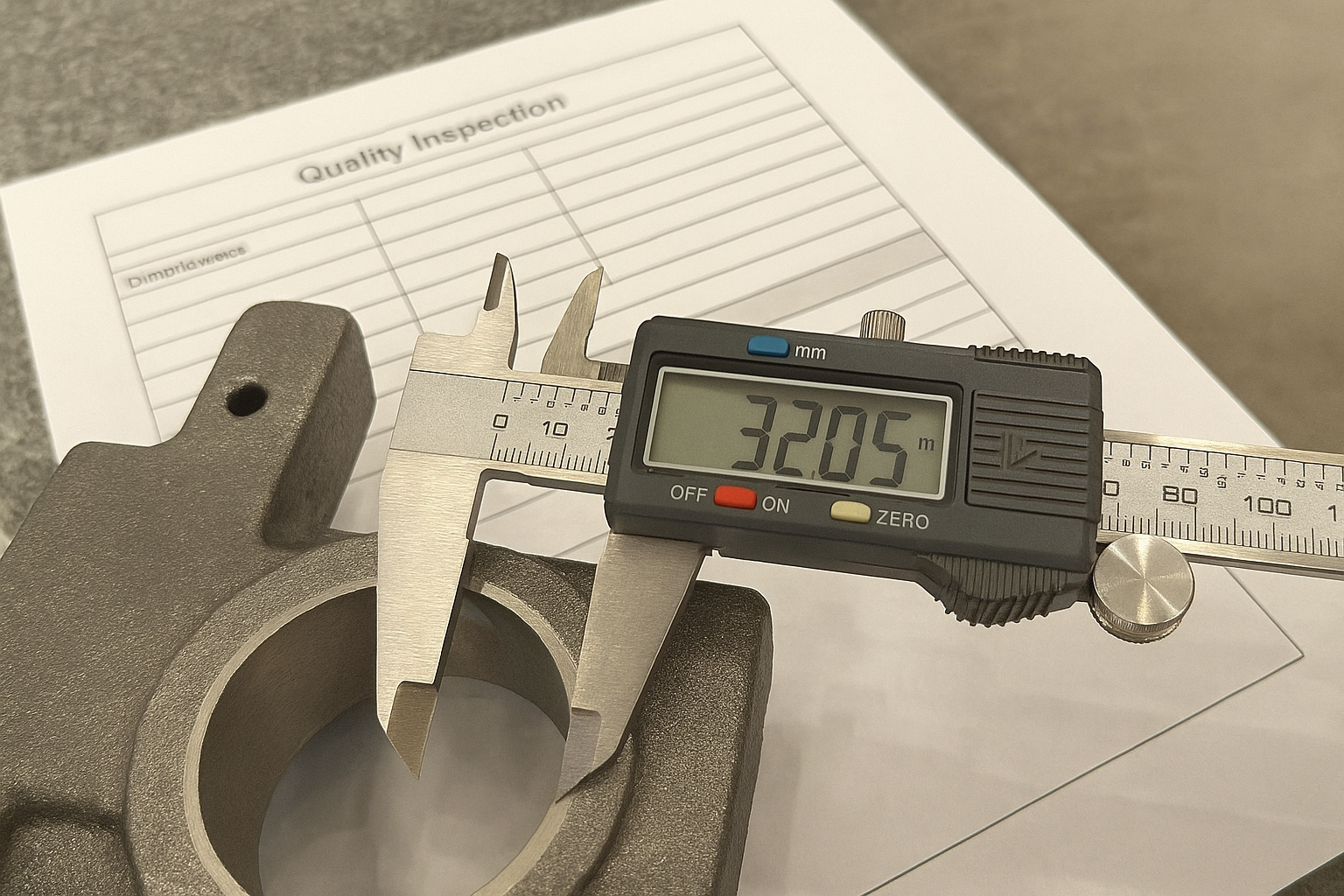

Comprehensive quality inspection including dimensional accuracy and defect detection.

Our comprehensive 9-step aluminum die casting process combines precision engineering with advanced technology, delivering superior quality aluminum components with exceptional dimensional accuracy and surface finish.

Get expert consultation & quote

Enhance your aluminum castings with our comprehensive range of surface finishing processes. From corrosion protection to aesthetic enhancement, we deliver superior results for demanding applications.

Our advanced anodizing process creates a durable, corrosion-resistant oxide layer that significantly extends component lifespan while providing excellent surface hardness and wear resistance.

Electrostatic powder coating provides superior durability, color consistency, and environmental resistance for outdoor applications.

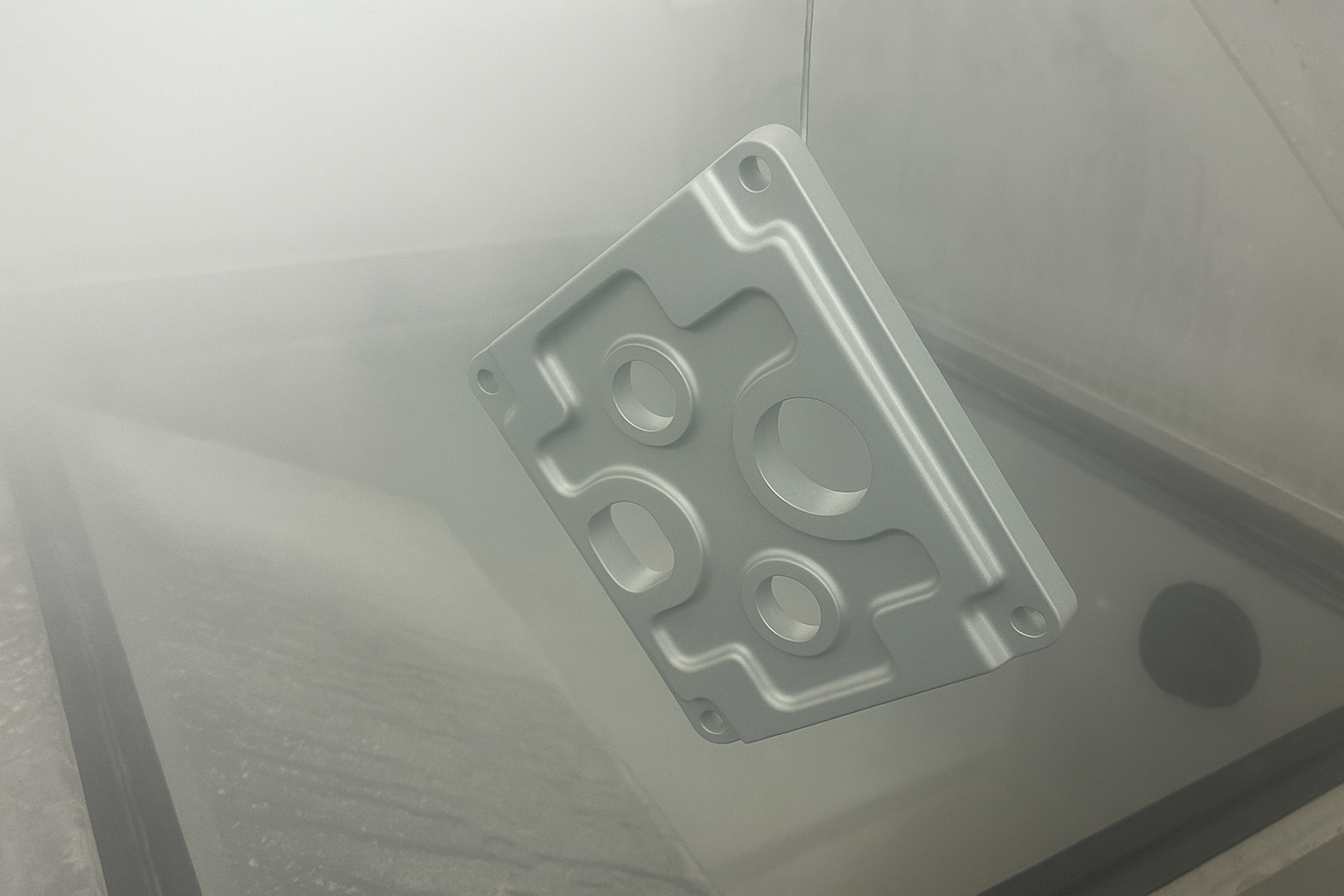

Precision surface preparation using controlled abrasive blasting for optimal surface roughness and coating adhesion.

CNC machining for critical surfaces requiring precise dimensions, tight tolerances, and superior surface finish quality.

| Treatment Type | Corrosion Resistance | Wear Resistance | Aesthetic Appeal | Cost Efficiency |

|---|---|---|---|---|

| Anodizing |

|

|

|

|

| Powder Coating |

|

|

|

|

| Sandblasting |

|

|

|

|

| Precision Machining |

|

|

|

|

Our surface treatment processes comply with international standards and undergo rigorous quality control to ensure consistent, reliable results for your critical applications.

State-of-the-art inspection technology ensures every component meets the highest quality standards with precision measurement and comprehensive material analysis.

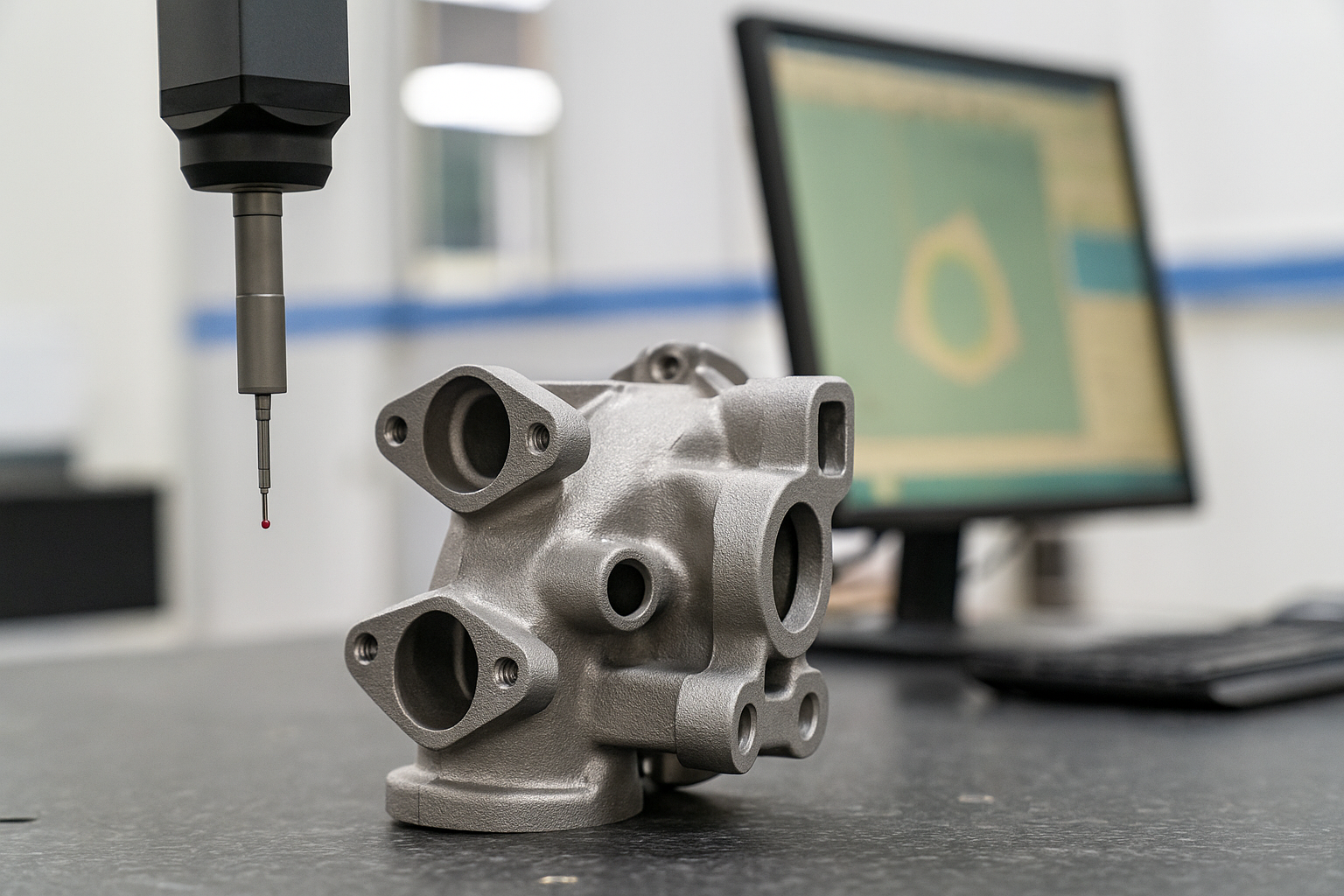

Our advanced CMM systems provide ultra-precise dimensional verification with micron-level accuracy, ensuring every casting meets your exact specifications.

Micron-level precision for critical dimensional verification

Complete form, position, and profile tolerance verification

Digital inspection certificates with full traceability

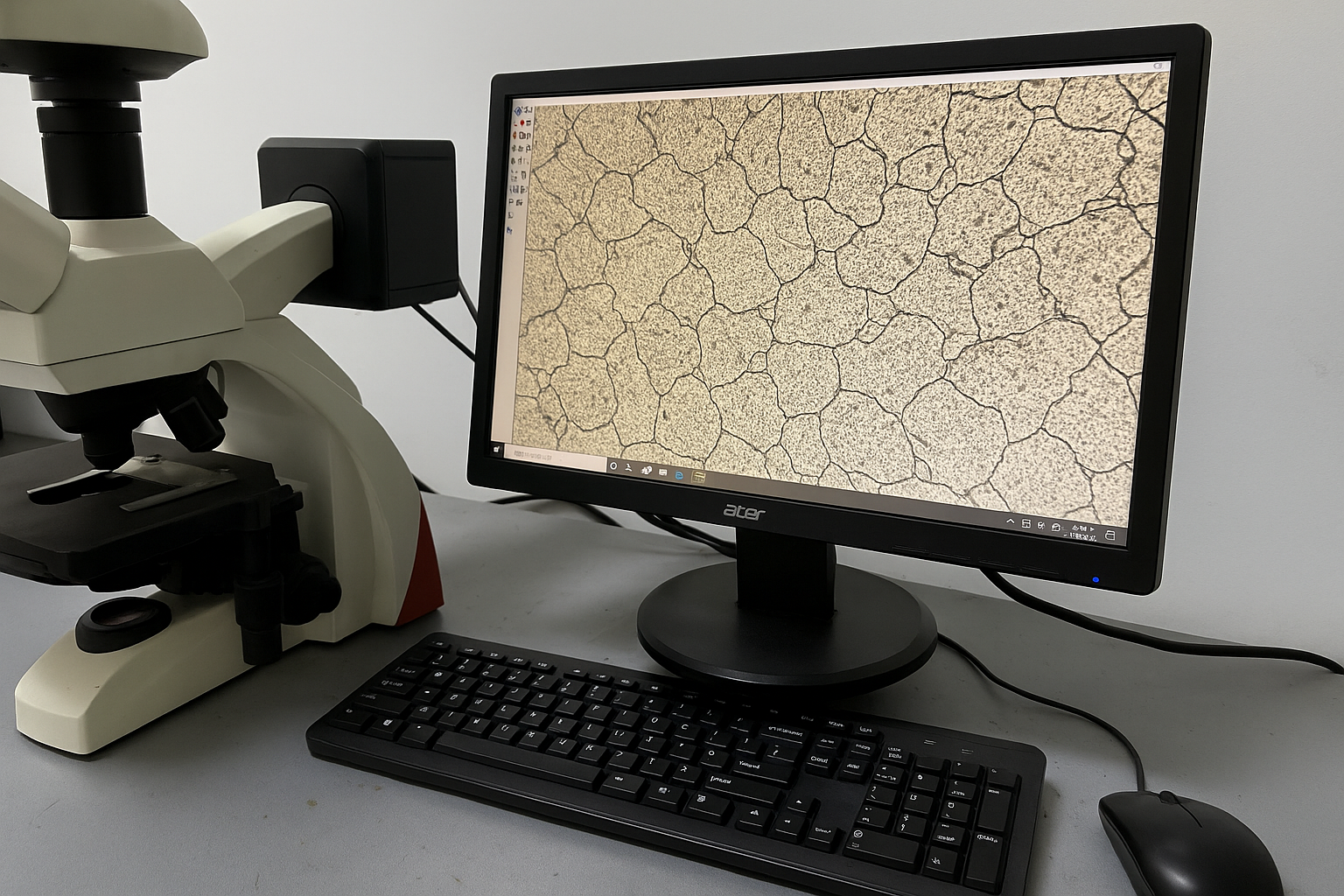

Advanced metallographic analysis reveals internal structure, grain boundaries, and material composition to verify metallurgical properties and detect potential defects.

Grain size, phase distribution, and inclusion evaluation

Porosity, cracks, and segregation identification

High-resolution imaging with detailed analysis reports

Precise chemical composition verification using optical emission spectroscopy for material certification.

Comprehensive hardness evaluation using Brinell, Rockwell, and Vickers methods for mechanical properties.

Non-destructive testing methods including ultrasonic, magnetic particle, and penetrant testing.

Every component comes with comprehensive inspection reports, material certificates, and dimensional analysis ensuring full traceability and compliance with international standards.

Our precision aluminum casting solutions deliver exceptional lightweight performance, excellent corrosion resistance, and superior strength-to-weight ratio across critical industrial applications worldwide.

Lightweight engine blocks, transmission housings, and suspension components for improved fuel efficiency and performance.

EMI shielding enclosures, heat sinks, and protective housings for electronic equipment and telecommunications systems.

Ultra-lightweight structural components, brackets, and housings meeting stringent aerospace standards for aircraft and defense systems.

Precision-engineered components for manufacturing equipment, pumping systems, and industrial automation machinery.

Corrosion-resistant marine components for vessels, offshore platforms, and coastal infrastructure exposed to harsh saltwater environments.

Critical components for renewable energy systems, power generation equipment, and energy storage solutions requiring lightweight durability.

Our engineering team is ready to help you select the optimal aluminum alloy and casting process for your specific application requirements.

Experience our world-class production facilities where precision meets innovation. Our advanced manufacturing capabilities ensure exceptional quality in every custom aluminum component.

Precision aluminum casting with automated quality control

ISO certified testing and inspection facilities

Secure storage and global shipping capabilities

CNC precision finishing and custom modifications

High-temperature melting and molding processes

Innovation lab for custom solution development

Get comprehensive answers to common questions about our premium aluminum casting services, from technical specifications to global delivery and quality assurance.

Our technical experts and engineering team are ready to discuss your specific aluminum casting requirements and provide personalized solutions tailored to your industry needs.

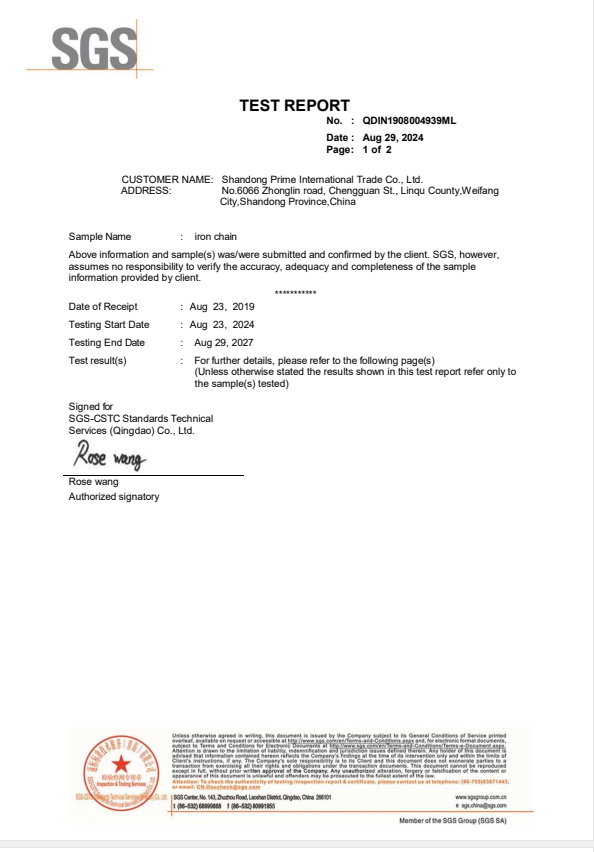

Our commitment to excellence is validated through rigorous international certifications, proprietary patents, and comprehensive quality management systems.

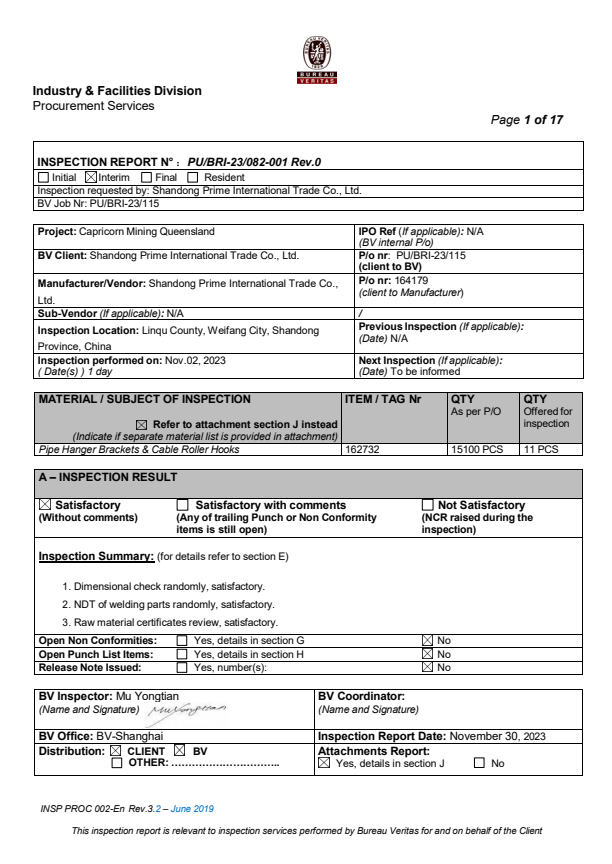

International standard for quality management systems, ensuring consistent quality and customer satisfaction across all production processes.

Global leader in inspection, verification, testing and certification services validating our quality standards and material integrity.

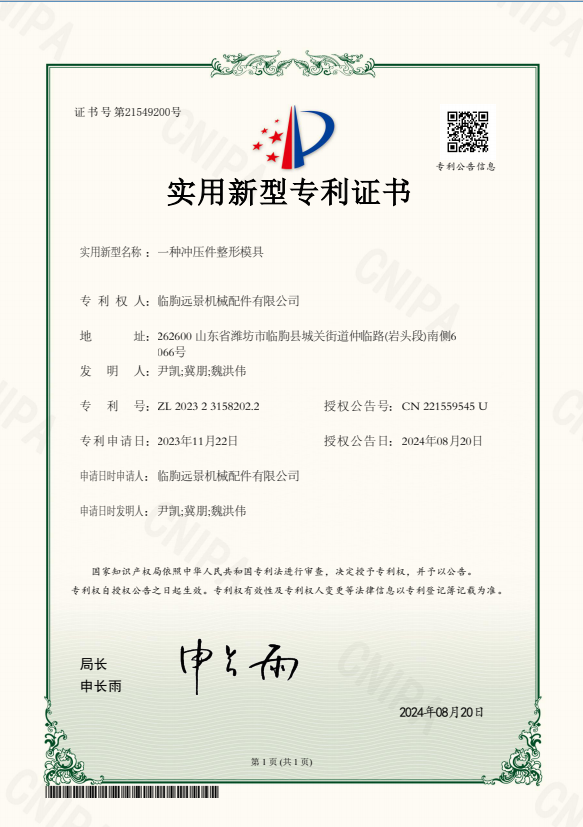

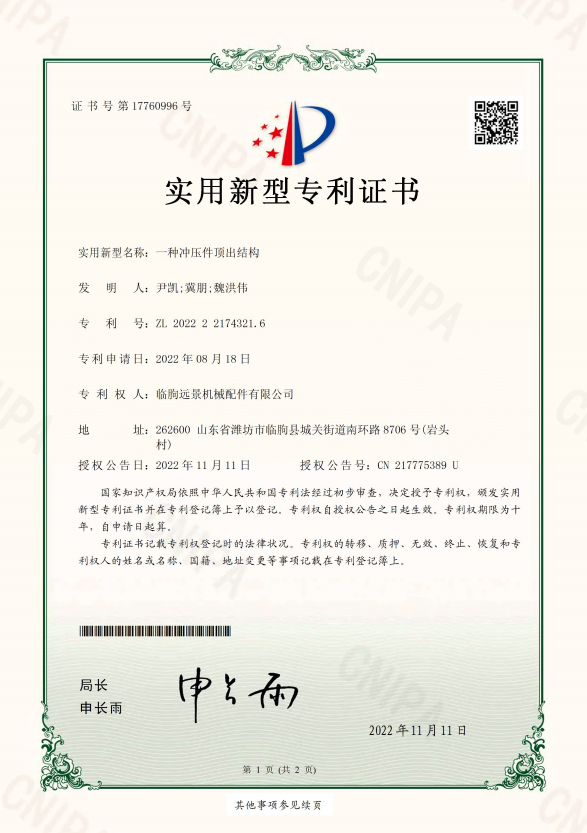

Innovative casting technologies and processes protected by multiple patents, ensuring superior quality and production efficiency.

Share your project requirements with us. Our engineering team will provide a detailed quote and technical consultation within 24 hours.

At Shandong Prime International Trade Co., Ltd., we understand the confidential nature of your industrial projects. Your trust is our foundation.

All technical drawings, specifications, and project details are stored securely and never shared with third parties.

Our quality management system includes strict data protection protocols, ensuring your information remains confidential.

Our certified engineers review your requirements with complete discretion and professional integrity.

Since 1993, we've built lasting relationships with global clients through transparency, reliability, and confidentiality.

We respond to all inquiries within 24 hours with detailed technical consultation and competitive pricing.