Your One-Stop Solution for High-Quality Metal Casting, From Design to Delivery ISO 9001 Certified, 99.2% On-Time Delivery, Get a Quote in 24 Hours.

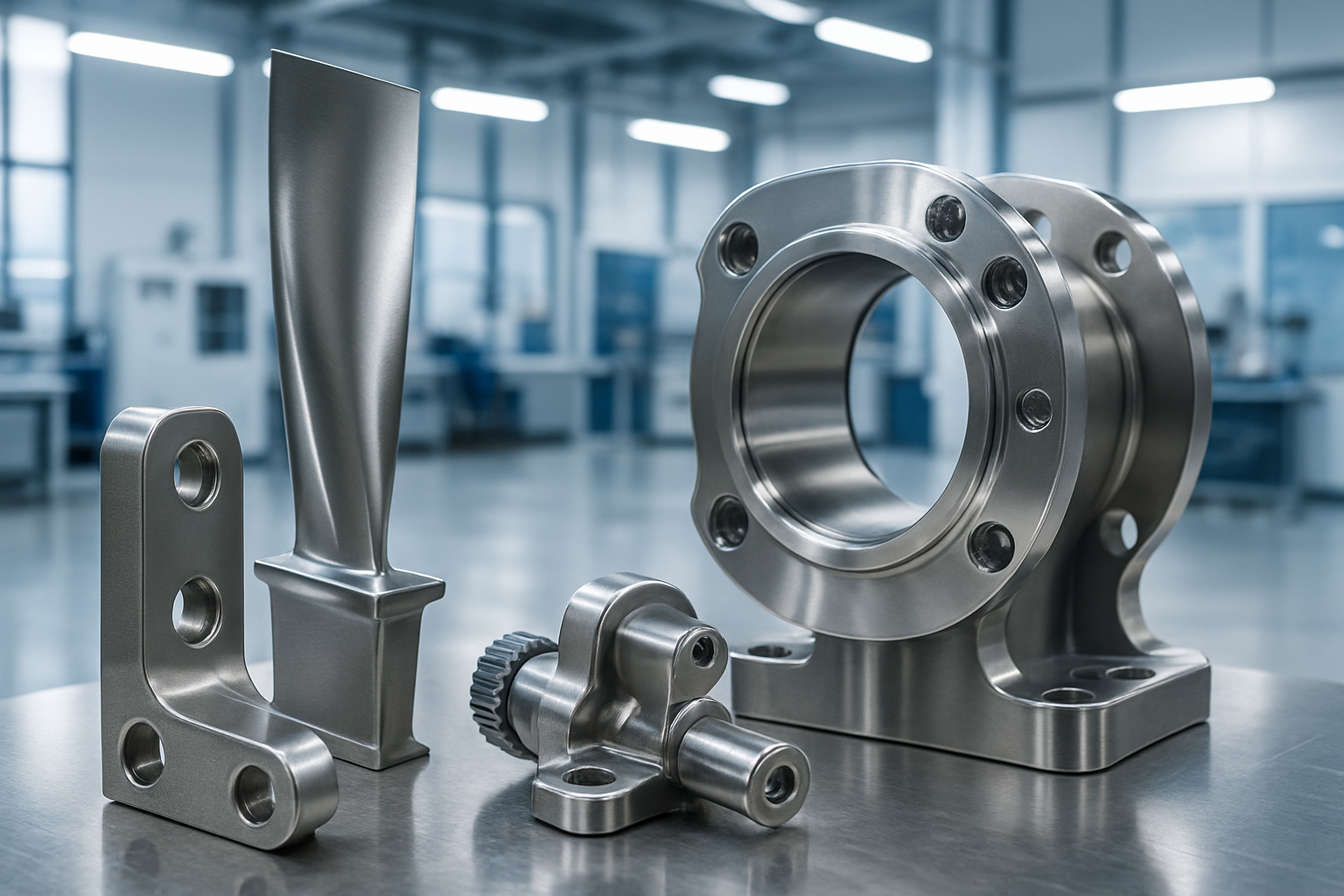

Precision-engineered steel components delivering superior strength, durability, and exceptional performance across heavy-duty industrial applications.

High-temperature steel components for extreme environments.

🔥 For waste incineration, biomass boilers, cement & lime kilns

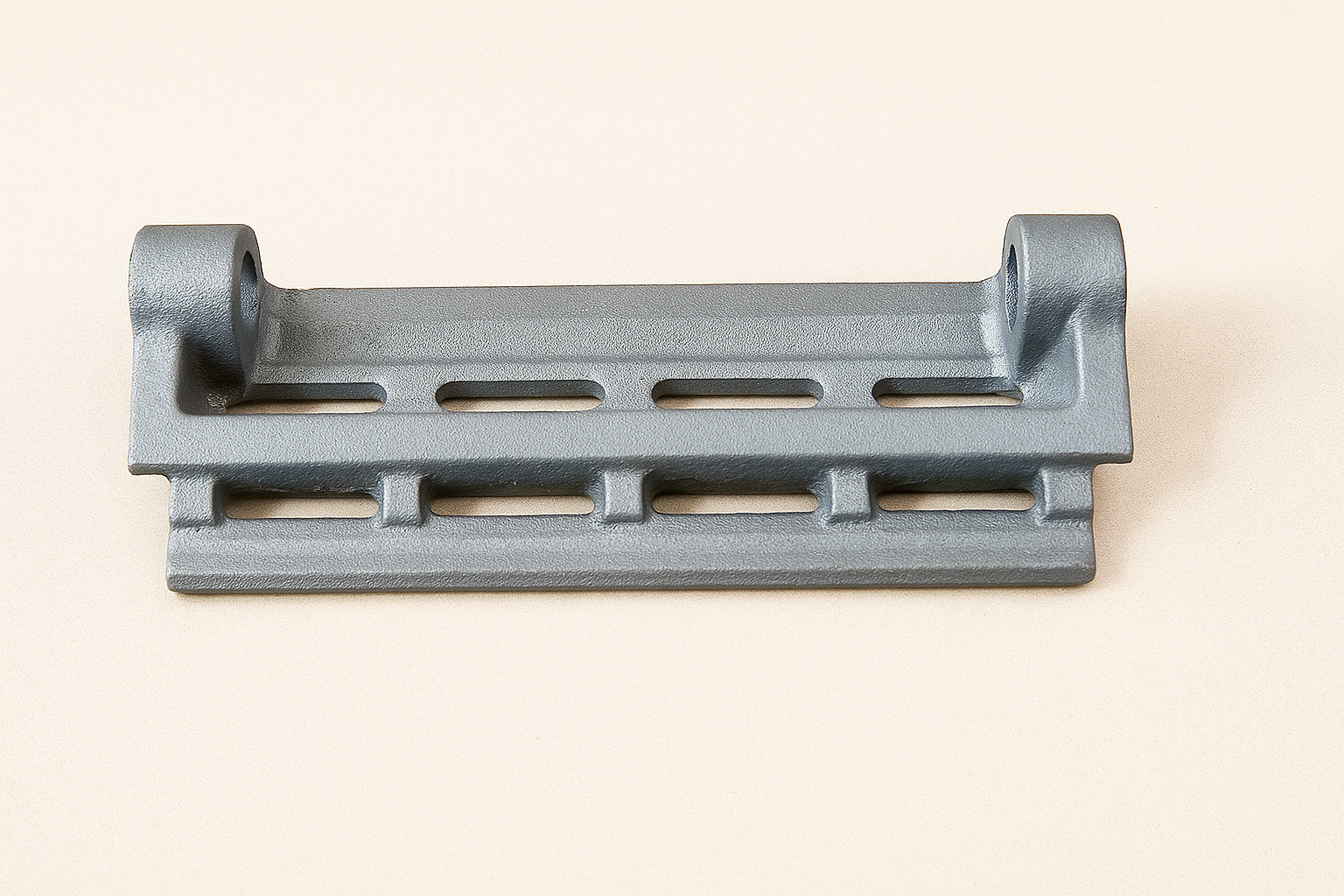

Heavy-duty components for abrasive environments.

⚡ For mining, construction, material handling industries

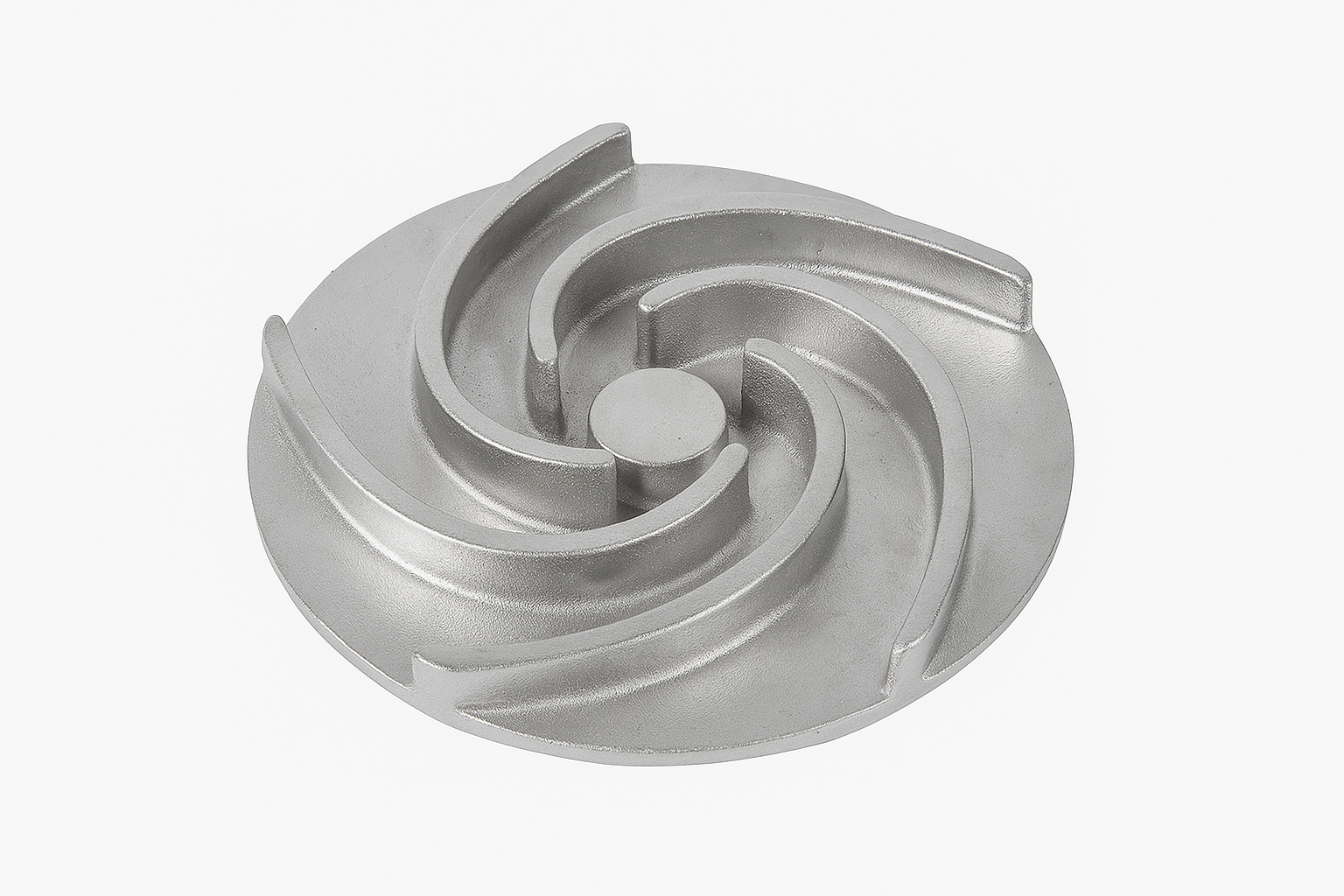

High-precision components for critical applications.

🔧 For petroleum, chemical, power equipment fields

Custom components for mechanical systems.

⚙️ Custom manufacturing per customer drawings & specs

Complete custom casting solutions with full services.

🎯 From sample development to mass production support

🎯 Meeting the industrial engineering needs of high strength, high precision, and complex working conditions.

Complete manufacturing solutions to meet all your requirements

High-precision finishing

Material strengthening

Surface protection

Spectral, NDT, CMM inspection

Comprehensive range of premium steel casting materials engineered for superior performance across diverse industrial applications.

| Material Grade | Composition | Tensile Strength | Yield Strength | Applications | Certification |

|---|---|---|---|---|---|

|

45# Carbon Steel

Most Popular

Medium Carbon Steel

|

C: 0.42-0.50% Mn: 0.50-0.80% Si: 0.17-0.37% |

600-750 MPa | 355 MPa min | Gears, Shafts, Machine Parts, General Engineering | ISO 9001 |

|

ASTM A216 WCB

Carbon Steel

|

C: 0.30% max Mn: 0.50-1.00% Si: 0.60% max |

485-655 MPa | 250 MPa min | Valves, Pumps, General Engineering | ISO 9001 |

|

ASTM A352 LCB

Low Temperature Steel

|

C: 0.30% max Mn: 0.50-1.00% Ni: 2.0-3.0% |

485-655 MPa | 250 MPa min | Cryogenic Applications, LNG Equipment | ISO 9001 |

|

ASTM A217 WC6

Chrome-Moly Steel

|

C: 0.05-0.20% Cr: 1.00-1.50% Mo: 0.44-0.65% |

550-750 MPa | 345 MPa min | High Temperature, Power Plants | ISO 9001 |

|

ASTM A743 CF8M

Stainless Steel

|

C: 0.08% max Cr: 18.0-21.0% Ni: 9.0-12.0% |

515 MPa min | 205 MPa min | Corrosive Environments, Marine | ISO 9001 |

|

ASTM A890 4A

Duplex Stainless

|

C: 0.04% max Cr: 21.0-23.0% Ni: 4.5-6.5% |

620 MPa min | 400 MPa min | Oil & Gas, Chemical Processing | ISO 9001 |

|

ASTM A216 WCC

Carbon Steel

|

C: 0.25% max Mn: 0.50-1.20% Si: 0.60% max |

485-655 MPa | 250 MPa min | Medium Pressure Applications | ISO 9001 |

All materials undergo rigorous testing including chemical composition analysis, mechanical property testing, and dimensional inspection.

Standard materials available from stock with 7-14 day lead times. Custom compositions available with 3-4 week production schedule.

Compliance with ASTM, ASME, DIN, JIS, and GB standards. Full material traceability and certification documentation provided.

Leading steel casting manufacturer with 30+ years of expertise, specializing in lost wax casting, lost foam casting, and sand core casting processes to deliver high-quality steel components with superior strength, durability and precision engineering.

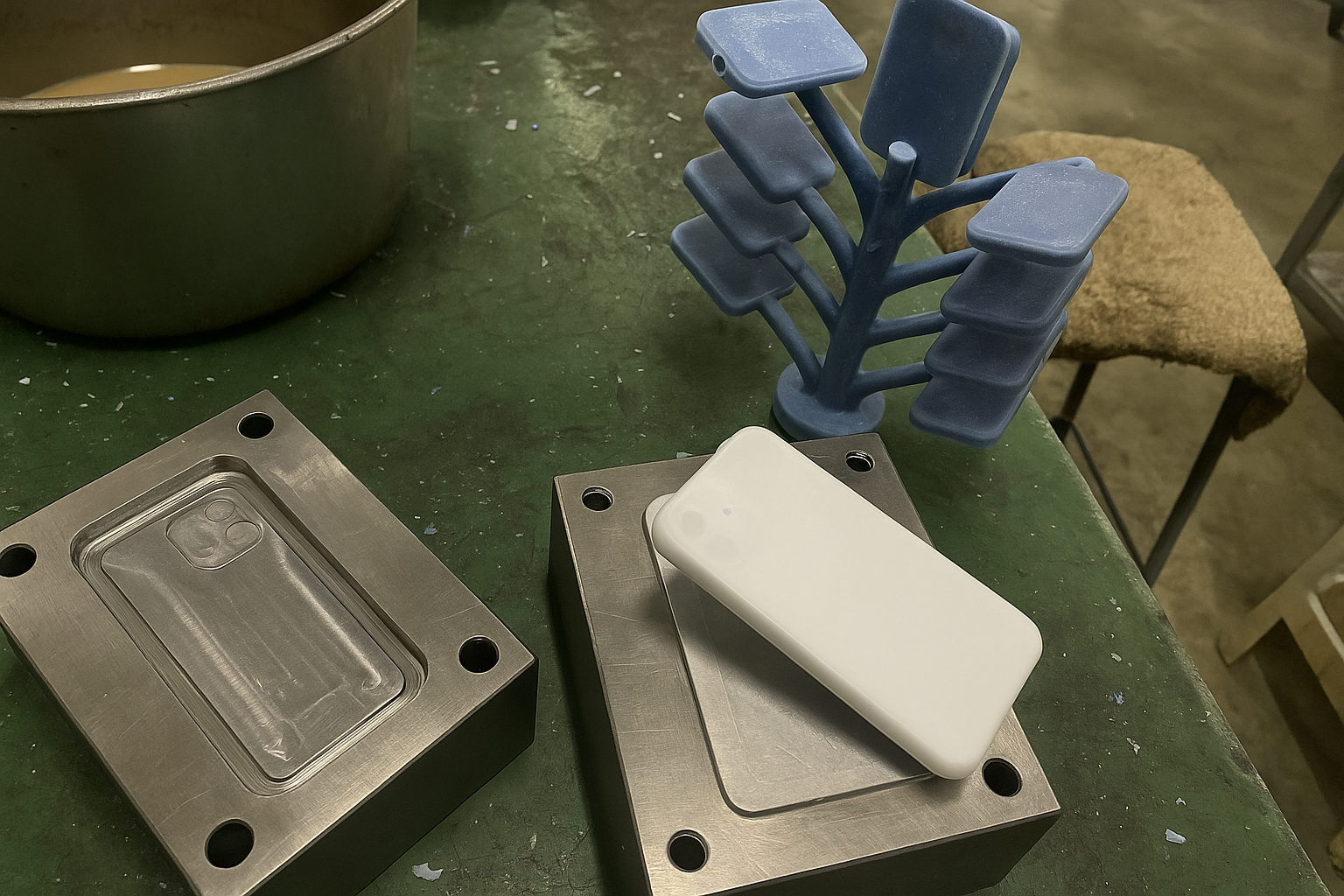

Creating precise wax patterns through advanced injection molding techniques, ensuring exact dimensional accuracy for complex steel casting geometries and intricate component details.

Multiple wax patterns attached to a central sprue forming a tree structure for efficient casting.

Repeated dipping in ceramic slurry and fine sand coating, dried layer by layer forming strong ceramic shell.

Ceramic-coated wax tree heated in autoclave to melt out wax, leaving hollow ceramic shell mold.

Empty ceramic shell fired at 900-1100°C to harden and remove wax residues for molten metal resistance.

Stainless steel melted in induction furnace under controlled atmosphere, poured into preheated ceramic shell.

After solidification, ceramic shell mechanically broken or blasted away revealing rough stainless steel castings.

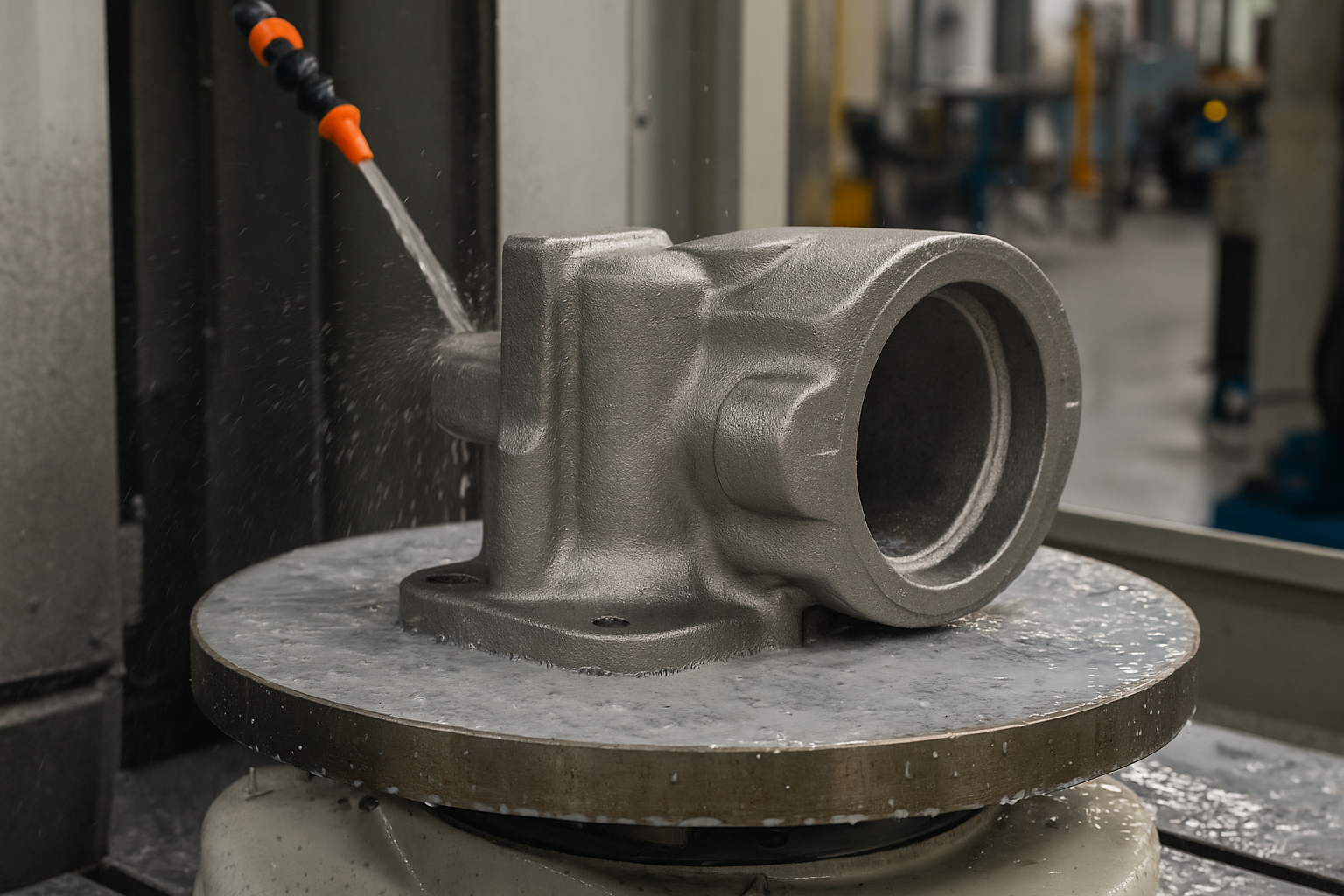

Castings cut from tree, gates removed, parts undergo grinding, shot blasting and polishing for precise surface quality.

Solution annealing applied to optimize stainless steel mechanical properties and corrosion resistance.

Comprehensive dimensional inspection, surface analysis, and NDT testing including X-ray and dye penetrant testing.

High tensile strength and excellent wear resistance

Economical for complex shapes and large-scale manufacturing

Carbon steel, alloy steel, and specialty steel compositions

Expert steel casting solutions & competitive pricing

Advanced surface finishing solutions that enhance durability, performance, and aesthetic appeal of your steel casting components across demanding industrial applications.

Our comprehensive surface treatment capabilities transform raw steel castings into high-performance components that withstand extreme conditions while maintaining dimensional accuracy and superior finish quality.

Removes scale, rust, and surface contaminants while creating optimal surface profile for subsequent treatments.

Electrostatic powder application followed by thermal curing for superior durability and uniform finish.

Zinc coating process providing exceptional corrosion protection for outdoor and marine applications.

CNC machining for tight tolerances and smooth surface finishes meeting exact specifications.

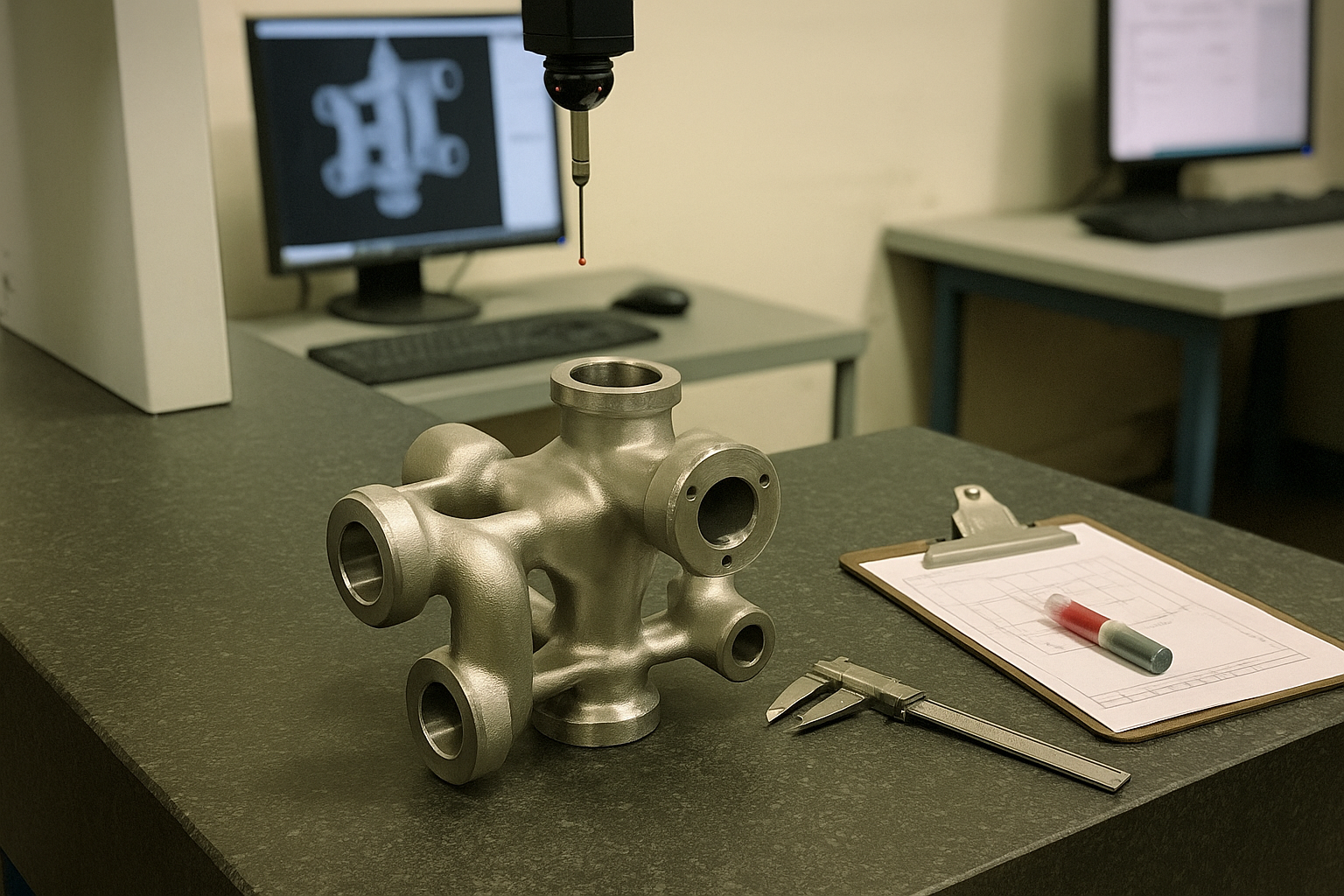

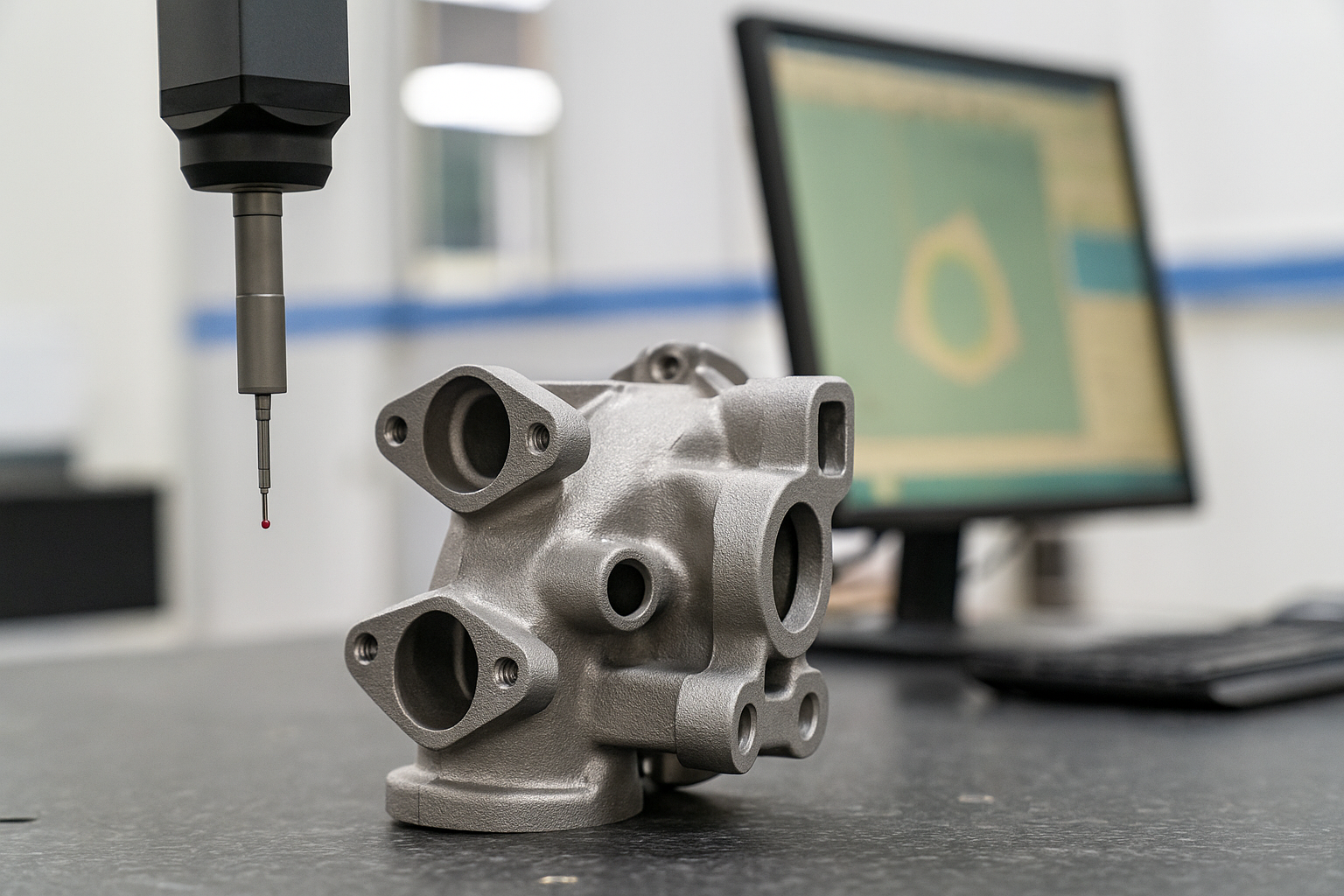

State-of-the-art inspection technology ensures every component meets the highest quality standards with precision measurement and comprehensive material analysis.

Our advanced CMM systems provide ultra-precise dimensional verification with micron-level accuracy, ensuring every casting meets your exact specifications.

Micron-level precision for critical dimensional verification

Complete form, position, and profile tolerance verification

Digital inspection certificates with full traceability

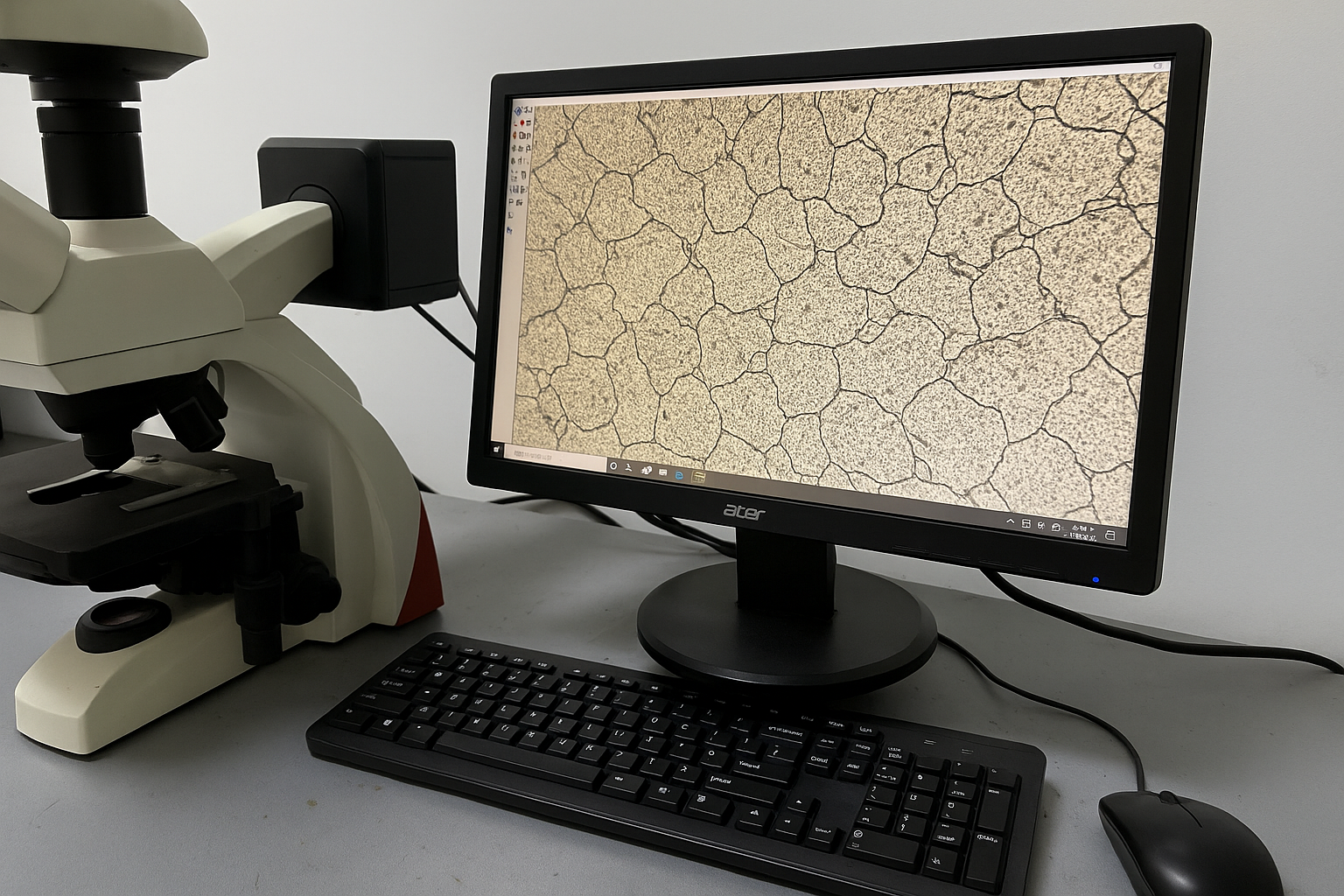

Advanced metallographic analysis reveals internal structure, grain boundaries, and material composition to verify metallurgical properties and detect potential defects.

Grain size, phase distribution, and inclusion evaluation

Porosity, cracks, and segregation identification

High-resolution imaging with detailed analysis reports

Precise chemical composition verification using optical emission spectroscopy for material certification.

Comprehensive hardness evaluation using Brinell, Rockwell, and Vickers methods for mechanical properties.

Non-destructive testing methods including ultrasonic, magnetic particle, and penetrant testing.

Every component comes with comprehensive inspection reports, material certificates, and dimensional analysis ensuring full traceability and compliance with international standards.

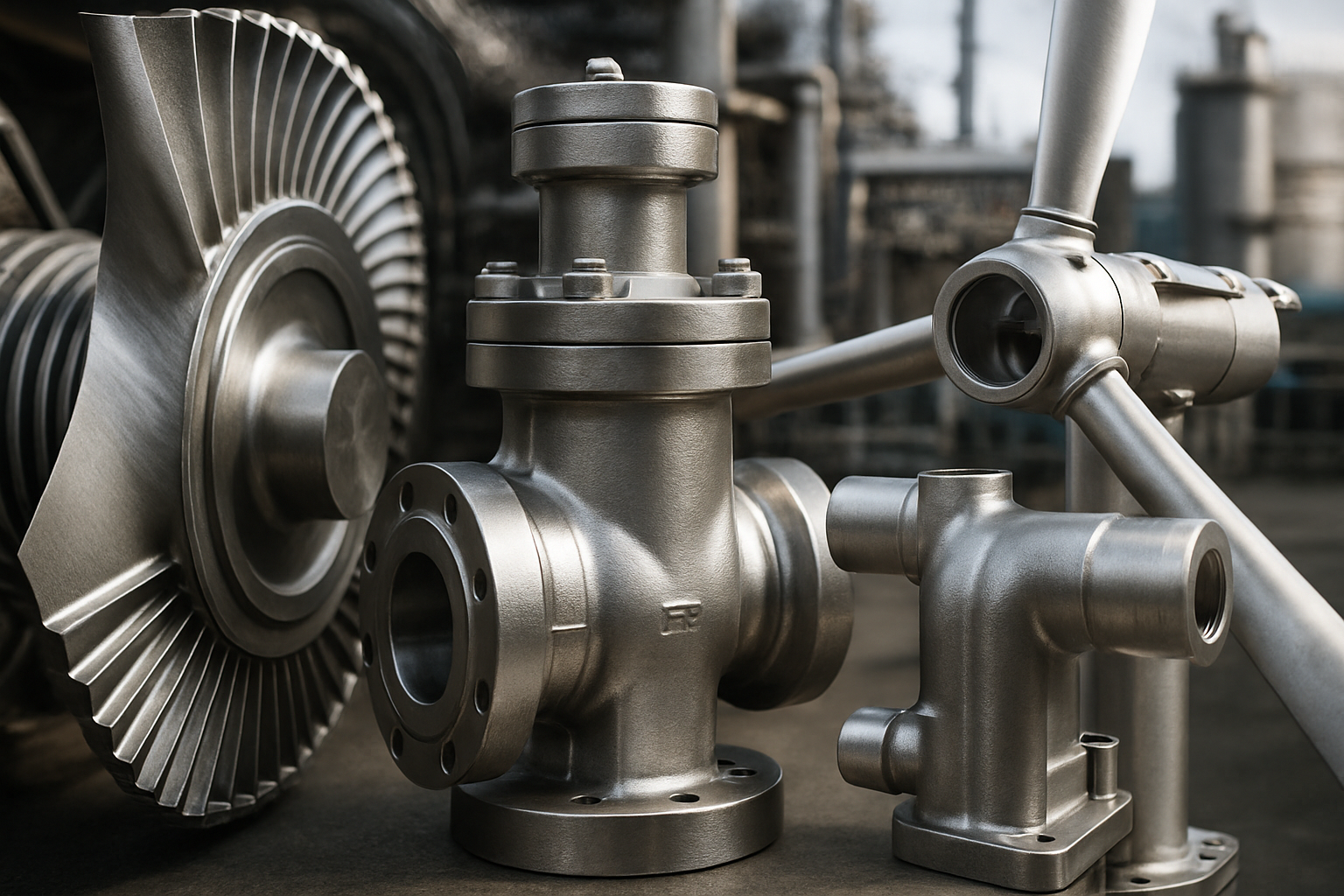

Precision-engineered steel casting solutions for industrial applications. Our advanced manufacturing capabilities deliver superior strength, durability, and dimensional accuracy for critical components across automotive, construction, energy, and heavy machinery sectors.

High-performance exhaust systems, turbocharger components, and engine parts requiring superior heat resistance and durability.

Critical components for power generation, oil & gas processing, and renewable energy systems demanding extreme reliability.

Precision-engineered components for manufacturing equipment, food processing, and chemical processing machinery.

Heavy-duty components for rail infrastructure, rolling stock, and high-speed train systems requiring exceptional strength.

Corrosion-resistant components for marine vessels, offshore platforms, and coastal infrastructure exposed to harsh environments.

Ultra-precision components meeting stringent aerospace standards for aircraft engines, structural elements, and defense applications.

With 30+ years of steel casting expertise and ISO certification, our engineering team delivers precision manufacturing solutions tailored to your industrial requirements across global markets.

Experience our world-class production facilities where precision meets innovation. Our advanced manufacturing capabilities ensure exceptional quality in every custom metal component.

Precision metal casting with automated quality control

ISO certified testing and inspection facilities

Secure storage and global shipping capabilities

CNC precision finishing and custom modifications

High-temperature melting and molding processes

Innovation lab for custom solution development

Get answers to common questions about our custom steel casting parts, from specifications to delivery and quality assurance.

Our technical experts are ready to discuss your specific steel casting requirements and provide personalized solutions for your manufacturing needs.

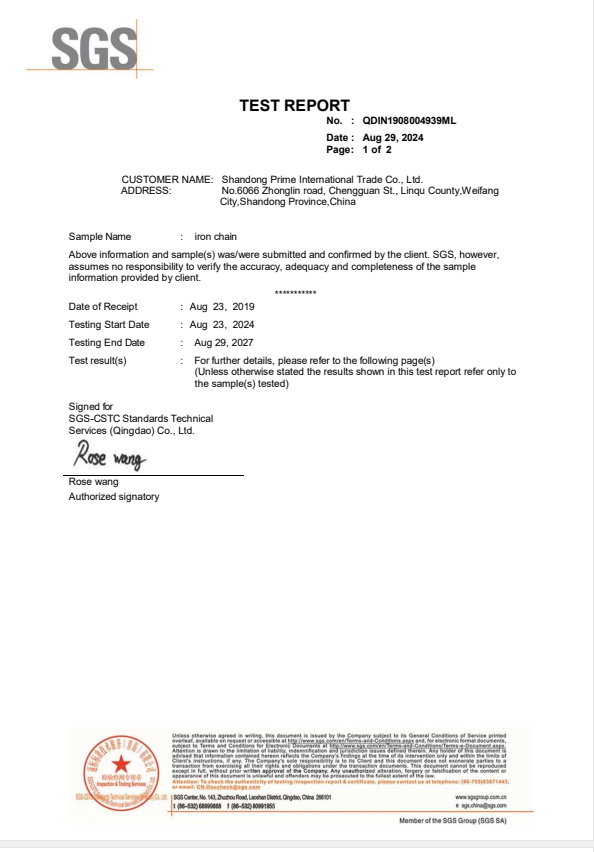

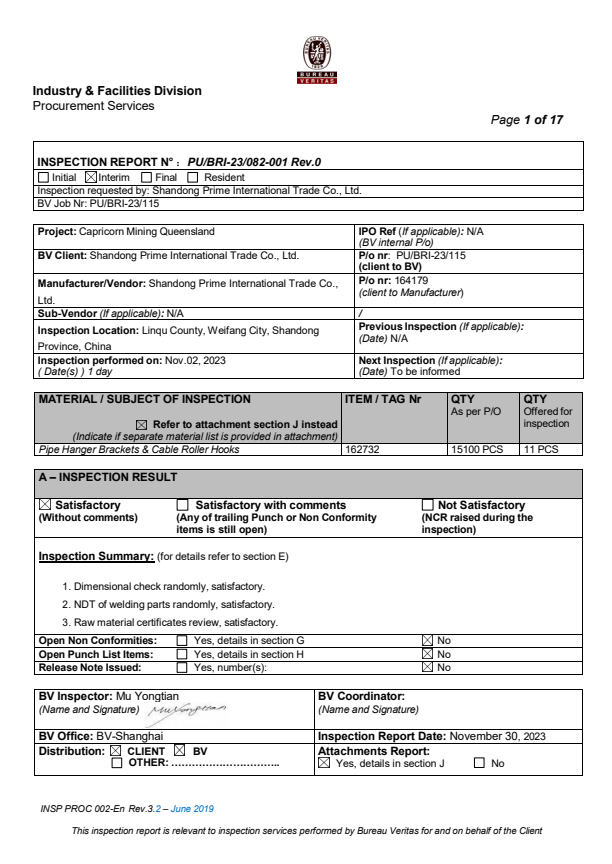

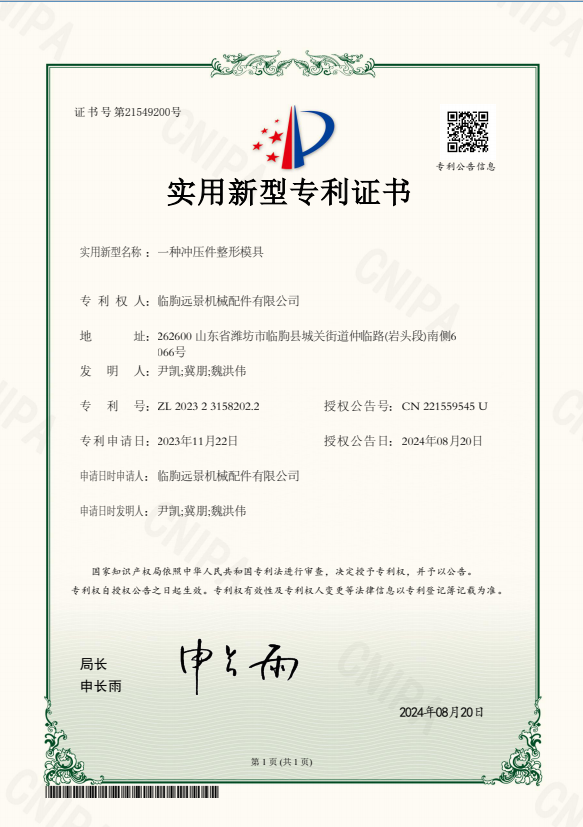

Our commitment to excellence is validated through rigorous international certifications, proprietary patents, and comprehensive quality management systems.

International standard for quality management systems, ensuring consistent quality and customer satisfaction across all production processes.

Global leader in inspection, verification, testing and certification services validating our quality standards and material integrity.

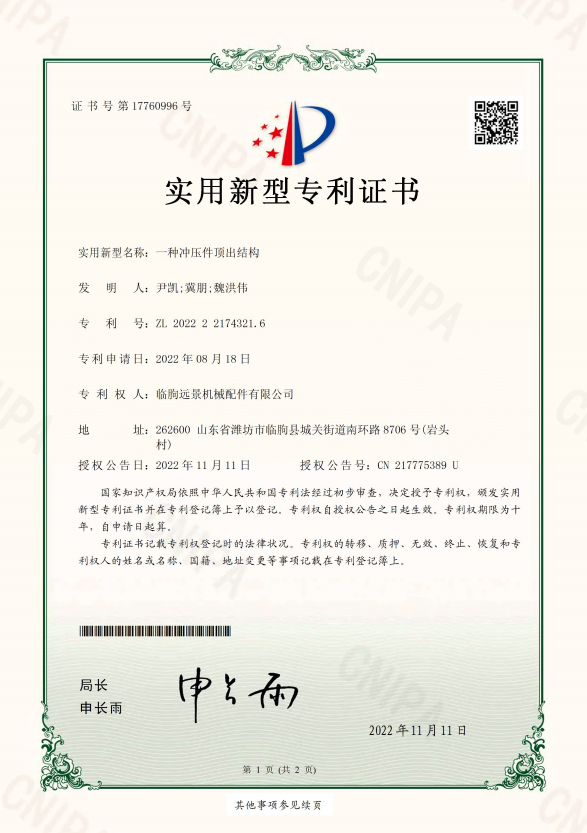

Innovative casting technologies and processes protected by multiple patents, ensuring superior quality and production efficiency.

Ready to discuss your metal casting needs? Contact our expert team for personalized solutions and competitive pricing.

We're committed to protecting your business information with the highest security standards.

All information is encrypted and stored securely. We never share your data with third parties without explicit consent.

Your project details and technical specifications remain strictly confidential throughout our partnership.

We follow international data protection regulations and give you full control over your personal information.

Our team commits to responding to all inquiries within 24 hours during business days.

Direct Contact: For urgent inquiries, call us at email [email protected]